- Contact Us

- |

- Jobs

- |

- About Us

- |

- |

-

- Personal information

- Organization

- Quotes

- Address book

- Login

- Don't have an account? Sign-up

Standard shield

- Home

- EMI shielding gaskets solutions

- EMI shielding gaskets

- Standard shield

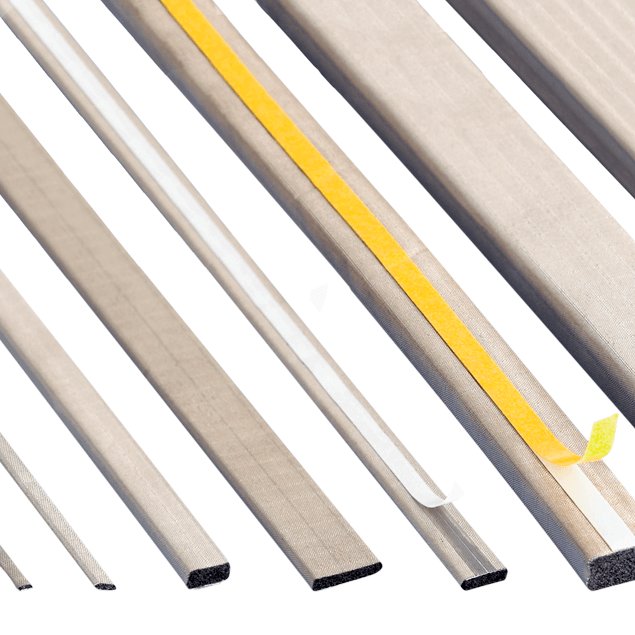

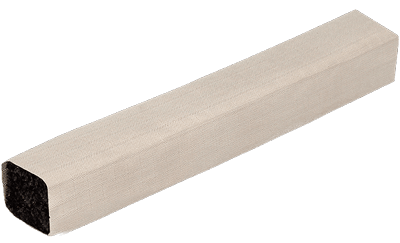

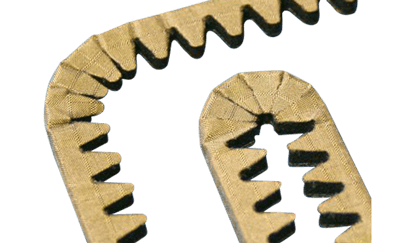

Standard Shield 7000 series is an economical HF (High Frequency) EMI shielding gasket which can be supplied in a wide range of dimensions. It is very effective in combination with stainless steel, copper and chrome-plated constructions.

Our 7000 series Standard shield EMI gaskets can be provided with a conductive or a non-conductive self-adhesive strip on the back for easy assembly.

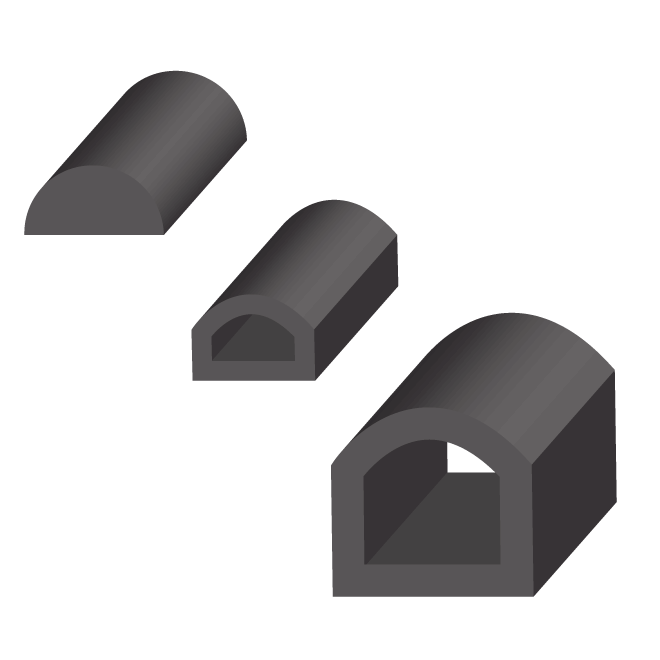

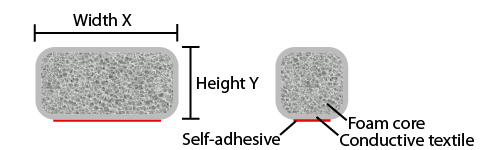

Standard shield consists of a foam core covered with highly electrically conductive textile. The following foam cores can be chosen:

- Neoprene foam core (foam code N)

- EPDM foam core (foam code E)

- Low closure force PVC foam (foam code P)

- Flame retardant UL94V-0 foam (foam code F)

For smaller widths than 3 mm we suggest to use the conductive adhesive (code 03). This guarantees excellent EMI/RFI shielding performance.

Please note: For special applications, different foam cores, conductive foils and fabrics are available on request.

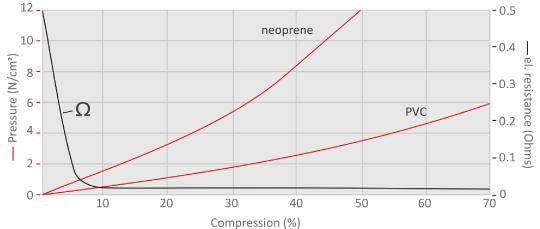

Shielding performance

Please note : These values are measured under laboratory conditions. Results may vary in other situations; please read our Guarantee.

Mechanical properties

Benefits

- Self-adhesive EMC gasket

- Easy to fit, can be cut with scissors

- Gasket can be die-cut (screw-holes, bites for easy bending etc.)

- Roll length of 1 to 1000 meters (Depending on width and height of the EMI gasket)

- High EMI/RFI shielding performance

- Low closure force

- EXTREMELY STRONG

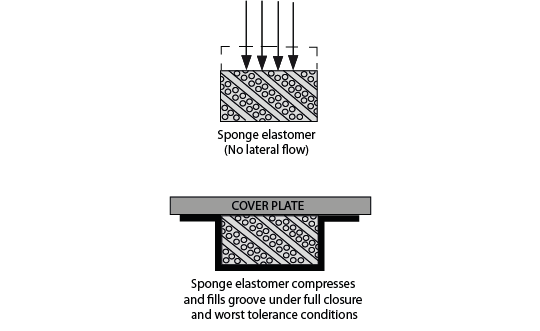

- Deflection 50%

Options

- CNC cut into specific lengths

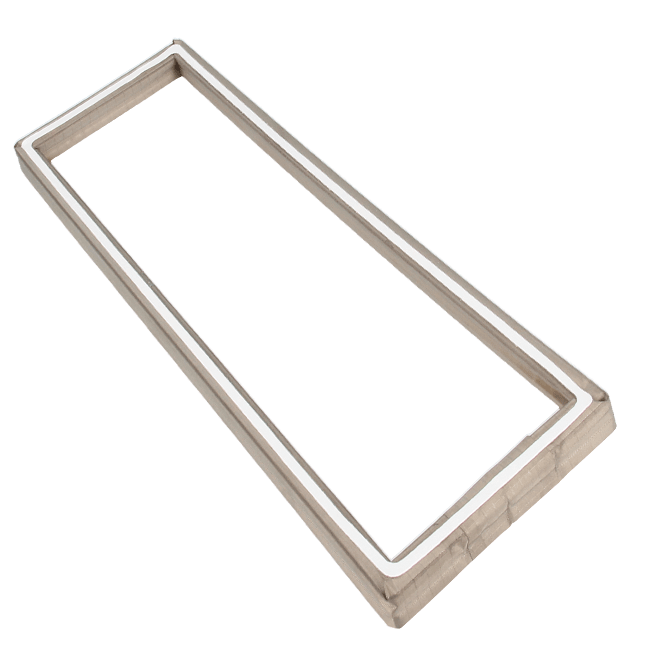

- Can be made into any shape or as a Frame gasket (according CAD drawing)

- Combination with water seal

- UL94V-0 flame retardant foam core (foam code F)

- Chemical resistant rubbers like EPDM

- Silicone sponge for high temperatures up to 220 °C

- Different conductive foils and fabrics

- EMI gaskets with cutouts according to drawing so that the gasket can be easily bend

Tape Specification

- 01 Standard self-adhesive placed in the middle

- 02 Without self-adhesive

- 03 With conductive self-adhesive (only recommended on small sizes)

- 06 Standard self-adhesive, asymmetrical

- 07 Standard self-adhesive placed on the side

Standard dimensions

| Width X (mm) | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Height Y(mm) | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 12 | 15 | 18 | 20 | 25 | 32 | 50 | |

| 1 | 2-1 | 3-1 | 4-1 | 5-1 | 6-1 | 7-1 | 8-1 | 9-1 | 10-1 | 12-1 | 15-1 | 18-1 | 20-1 | 25-1 | 32-1 | 50-1 | |

| 2 | 2-2 | 3-2 | 4-2 | 5-2 | 6-2 | 7-2 | 8-2 | 9-2 | 10-2 | 12-2 | 15-2 | 18-2 | 20-2 | 25-2 | 32-2 | 50-2 | |

| 3 | 3-3 | 4-3 | 5-3 | 6-3 | 7-3 | 8-3 | 9-3 | 10-3 | 12-3 | 15-3 | 18-3 | 20-3 | 25-3 | 32-3 | 50-3 | ||

| 4 | 4-4 | 5-4 | 6-4 | 7-4 | 8-4 | 9-4 | 10-4 | 12-4 | 15-4 | 18-4 | 20-4 | 25-4 | 32-4 | 50-4 | |||

| 5 | 5-5 | 6-5 | 7-5 | 8-5 | 9-5 | 10-5 | 12-5 | 15-5 | 18-5 | 20-5 | 25-5 | 32-5 | 50-5 | ||||

| 6 | 6-6 | 7-6 | 8-6 | 9-6 | 10-6 | 12-6 | 15-6 | 18-6 | 20-6 | 25-6 | 32-6 | 50-6 | |||||

| 8 | 7-8 | 8-8 | 9-8 | 10-8 | 12-8 | 15-8 | 18-8 | 20-8 | 25-8 | 32-8 | 50-8 | ||||||

| 9 | 9-9 | 10-9 | 12-9 | 15-9 | 18-9 | 20-9 | 25-9 | 32-9 | 50-9 | ||||||||

| 10 | 10-10 | 12-10 | 15-10 | 18-10 | 20-10 | 25-10 | 32-10 | 50-10 | |||||||||

| 12 | 12-12 | 15-12 | 18-12 | 20-12 | 25-12 | 32-12 | 50-12 | ||||||||||

Please contact us for custom sizes or more information.

High temperature version

The standard neoprene foam core can withstand temperatures up to 85 °C. If you have an application where a higher maximum temperature is required we can deliver the same type of EMI gasket with a FUBA foam core which also has a high deflection up to 65 %. This FUBA foam can withstand temperatures up to 220 °C. For more information see our High temperature resistant EMI gasket. When your application requires an even higher temperature, we can deliver this type of gasket with silicone foam core on request.

Stamped out patterns can be carried out on request

Optionally, these EMI gaskets can be provided with bites, cuts, holes or other patterns. These cut-outs/patterns may be used for easy bending or easy assembly of the EMI gasket.